Verlumina

A lamp shade crafted from a renewable

biomass source, showcasing the beautiful

potential of sustainable bioplastics.

Bioplastic Formula

Material Research

After numerous experiments with varying ratios of the ingredients were conducted, and a mixed gel of both agar and gelatin was found to have the best properties.

Experimental Molding Process

Learning to work with an unpredictable material and control its form.

DRAPE MOLDING

A flat sheet of bioplastic can be poured, left to partially dry, then draped into a mold. Similar to draping fabric, only simple curves can be accomplished.

PROCESS

Once draped, the material is buried in silica gel to rapidly dry the bioplastic and prevent mold growth

STRETCHING

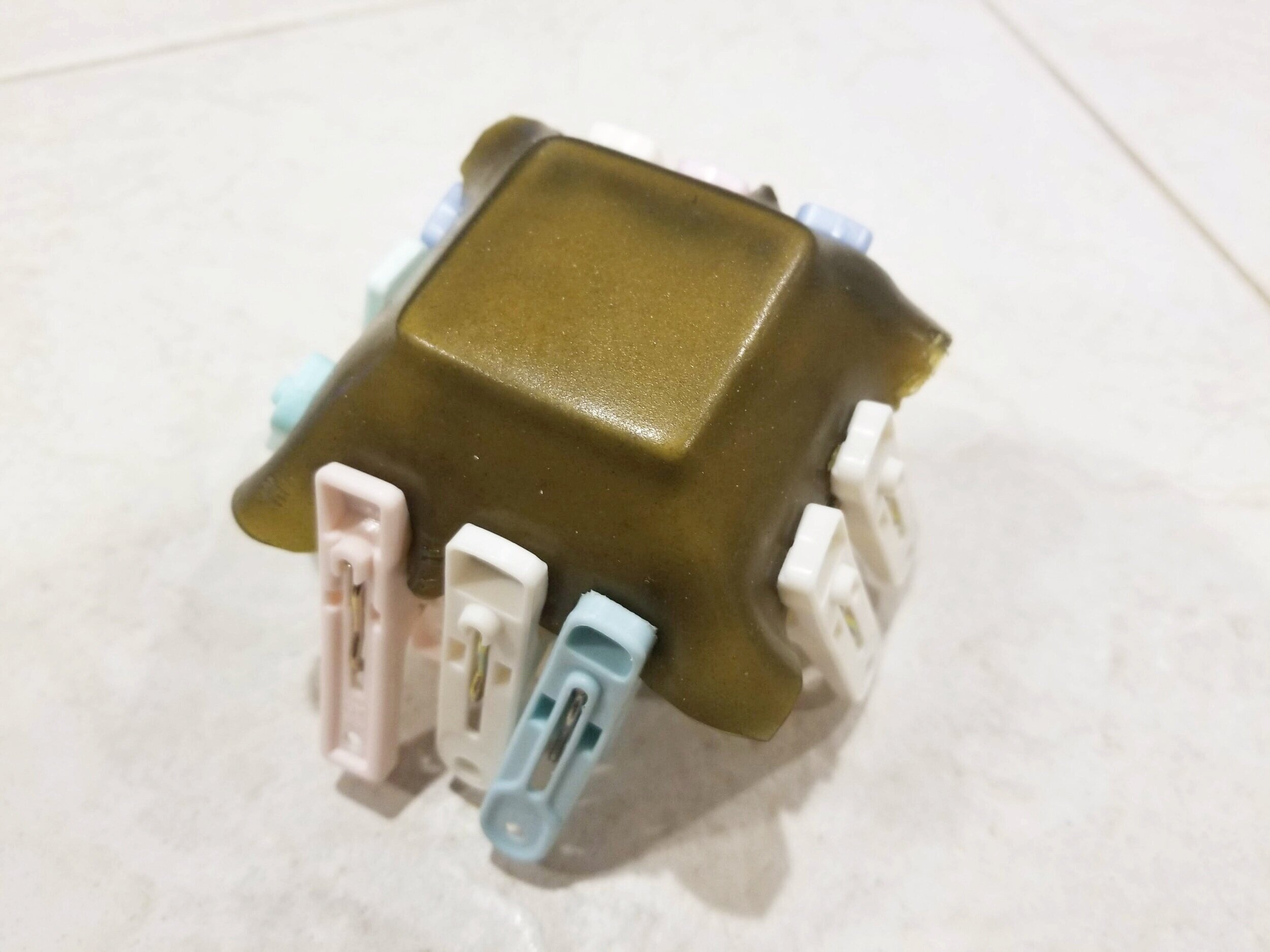

Like leather, the bioplastic can also be stretched around corners to form more exacting geometry.

Clips used to tightly hold stretched material

The bioplastic shrinks around the mold as it dries, forcing it to take on the mold’s exact geometry

DESIGN EXPLORATION

Inspired by the translucence of the material, I decided to design a lamp that would showcase the material’s beauty. Modules make up a dodecahedron that acts as a shade for a light.

Modules take advantage of the regular geometry accomplished when stretching the material, while also embracing the material’s natural tendency to drape and curl.

Each module is repeatable, yet entirely unique

COLORANT FROM LOCAL GRASS

GRASS CLIPPINGS : A WASTED RESOURCE

90 million gallons of water are used for growing grass for an average golf course in California, which is the highest nonagricultural use of water in the state. Furthermore, grass clippings are wasted and take up a large amount of space in composting sites and landfills.

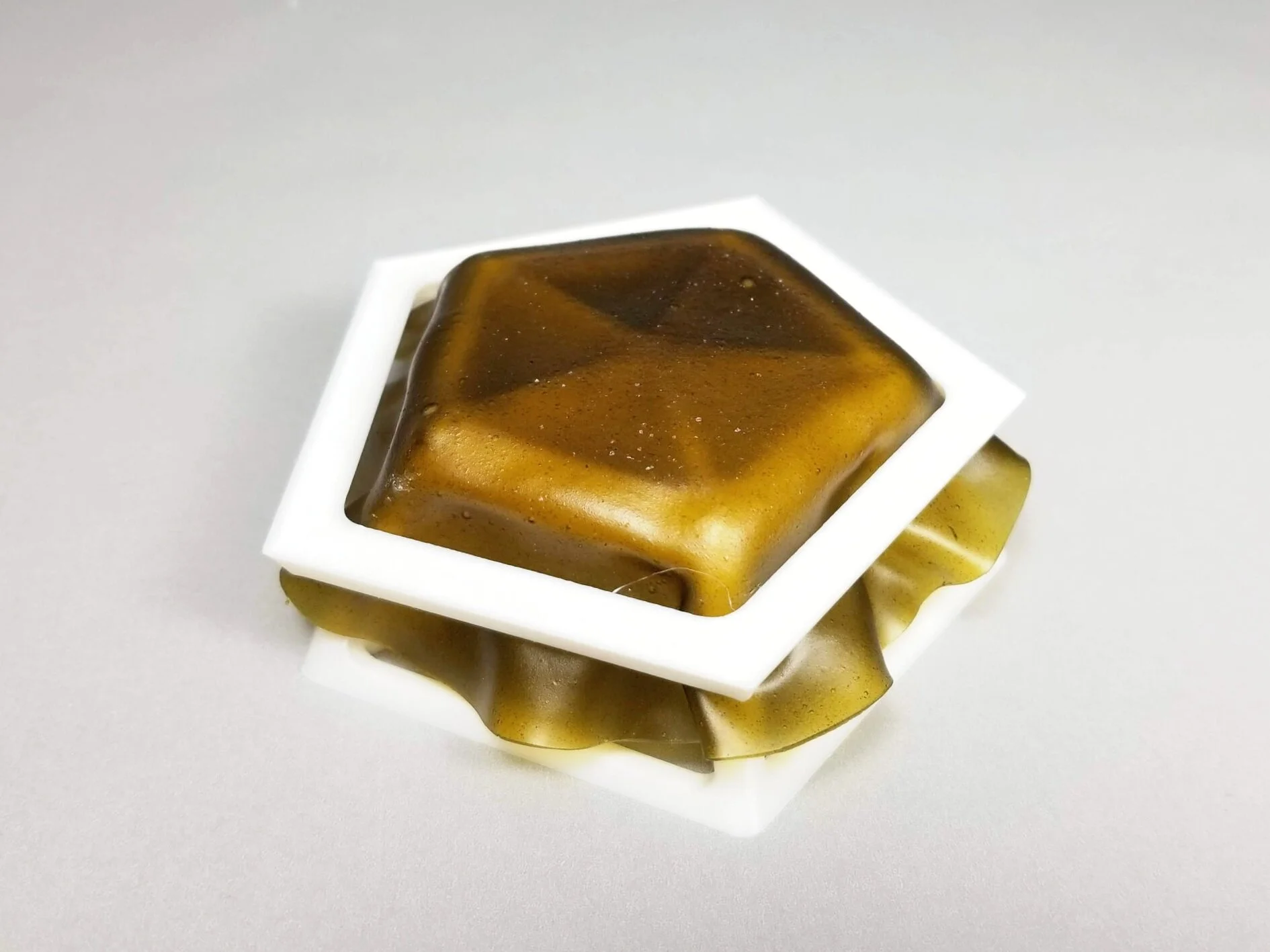

MOLD DESIGN

The reusable core and cavity of the mold were designed and 3D printed to form the bioplastic into a repeatable module.

The open frame allowed silica gel to quickly dry the bioplastic.

FIRST ITERATION

Material not able to drape naturally

Outer ring did not clamp material well

SECOND ITERATION

Bioplastic onstrained by walls, similar to original drape molding method

Shrinks around inner ring, creating sharper repeatable geometry at the base

PRODUCTION PROCESS

12 modules created in total

Cycle time (from pouring to dry product): ~ 36 hours

Modules held together with copper wire in corners

Each module consists of:

2g agar agar

15g gelatin

3.75g glycerol

75g distilled water

18g grass pigment